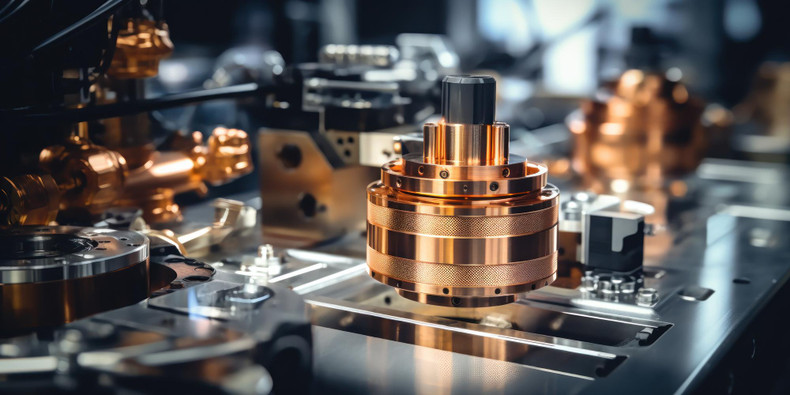

The tools and techniques we use are as important as the machinists' skills. High performance carbide end mills stand out as a crucial element in achieving precision, efficiency, and cost-effectiveness in various machining processes. Whether in aerospace, automotive, or general manufacturing, these tools have transformed the way we approach cutting and shaping materials.

In this post, we will explore the significant benefits of high performance carbide end mills and why they are indispensable in today's machining industry.

Increased Durability and Longevity

One of the most notable advantages of high performance carbide end mills is their remarkable durability. Unlike traditional high-speed steel (HSS) tools, carbide end mills can withstand higher temperatures and maintain their hardness, even in the most demanding conditions. This increased durability translates into a longer tool life, reducing the frequency of replacements and lowering overall production costs.

CGSTOOL's high performance carbide end mills, for example, are designed to handle extreme conditions without compromising on quality. This longevity is not only a cost-saving benefit but also enhances the reliability and efficiency of the machining process. By investing in carbide end mills, manufacturers can ensure that their operations run smoothly with minimal downtime due to tool wear and tear.

Superior Cutting Performance

The cutting performance of high performance carbide end mills is unparalleled. These tools are engineered to deliver precise cuts with exceptional accuracy. Their sharp cutting edges and ability to retain a keen edge for extended periods mean that manufacturers can achieve smoother finishes and tighter tolerances.

Transitioning to carbide end mills can significantly improve the quality of the finished product. This is particularly important in industries where precision is critical, such as aerospace and medical device manufacturing. The superior cutting performance of these tools ensures that each part meets the stringent quality standards required in these fields.

Higher Speeds and Feeds

High performance carbide end mills are designed to operate at higher speeds and feeds compared to their HSS counterparts. This capability is crucial in modern machining, where efficiency and productivity are paramount. By using carbide end mills, manufacturers can reduce cycle times and increase throughput, leading to higher overall productivity.

CGSTOOL's range of carbide end mills is optimized for high-speed machining, allowing operators to push the limits of their equipment without sacrificing quality. This results in faster production times and the ability to meet tight deadlines, giving manufacturers a competitive edge in the market.

Versatility in Material Applications

Another key benefit of high performance carbide end mills is their versatility. These tools are suitable for a wide range of materials, including hard metals, stainless steel, cast iron, and non-ferrous materials. This adaptability makes carbide end mills an ideal choice for manufacturers who work with diverse materials and need reliable performance across different applications.

Using carbide end mills from CGSTOOL, manufacturers can confidently tackle various machining tasks without the need for frequent tool changes. This versatility not only simplifies the machining process but also enhances overall efficiency by reducing the time spent on tool setup and adjustments.

Improved Surface Finish

Achieving a high-quality surface finish is a critical aspect of modern machining, especially in industries where aesthetic and functional properties are paramount. High performance carbide end mills excel in this area, providing superior surface finishes that meet the highest standards.

The precision engineering of carbide end mills ensures minimal tool deflection and vibration during cutting, resulting in smoother surfaces and reduced need for secondary finishing operations. This improved surface finish can be a significant advantage in applications where the final appearance and performance of the part are crucial, such as in the production of medical implants or aerospace components.

Cost-Effectiveness

While the initial cost of high performance carbide end mills may be higher than that of HSS tools, the long-term cost savings are substantial. The extended tool life, reduced need for replacements, and increased productivity all contribute to a lower overall cost of ownership.

Manufacturers who invest in carbide end mills from CGSTOOL benefit from reduced tooling costs over time. The enhanced performance and durability of these tools mean fewer interruptions and less expenditure on tool maintenance and replacement. This cost-effectiveness is a compelling reason for manufacturers to make the switch to high performance carbide end mills.

Environmental Benefits

In today's manufacturing landscape, sustainability is becoming increasingly important. High performance carbide end mills contribute to more environmentally friendly machining processes. Their longer lifespan and ability to maintain performance over extended periods mean less waste generated from worn-out tools.

Additionally, the efficiency gains achieved with carbide end mills translate into reduced energy consumption during machining operations. By using tools that operate at higher speeds and feeds, manufacturers can complete tasks more quickly and with less energy, contributing to a lower carbon footprint.

Conclusion

High performance carbide end mills have revolutionized modern machining, offering numerous benefits that enhance productivity, precision, and cost-efficiency. From their increased durability and superior cutting performance to their versatility and environmental advantages, these tools are essential for any manufacturer looking to stay competitive in today's market.

CGSTOOL's commitment to providing high-quality carbide end mills ensures that manufacturers can rely on tools that meet the highest performance and reliability standards. By incorporating these advanced tools into their machining processes, manufacturers can significantly improve efficiency and product quality, ultimately leading to greater success and profitability.

In conclusion, adopting high-performance carbide end mills is not just a smart choice but a necessity for modern machining operations. Their benefits extend far beyond the immediate advantages, paving the way for sustainable, efficient, and high-quality manufacturing.

Read More:Carbide Drills