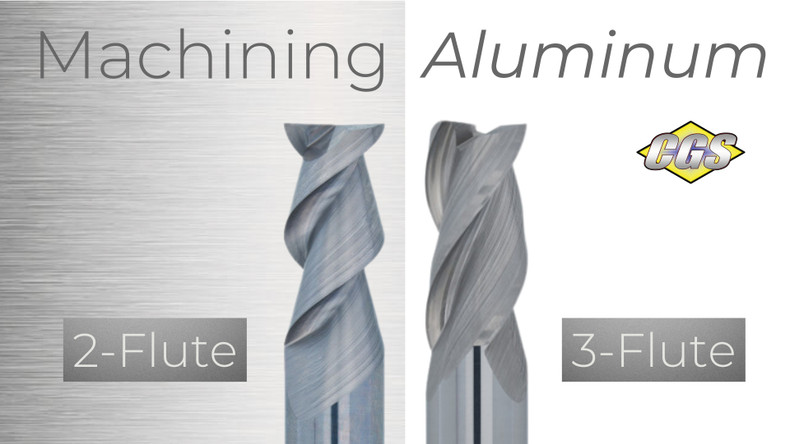

Aluminum is a widely used material known for both its machinability and versatility. To achieve precision and efficiency while using aluminum, using the correct endmill is crucial. Among the various types of end mills available, the 2-flute and 3-flute end mills stand out as the best options when machining aluminum. Here is a detailed breakdown of machining aluminum with 2 and 3-flute endmills.:

2-Flute End Mills

- Advantages:

- Better chip clearance: The larger gullet (space between the flutes) allows for easier evacuation of aluminum chips, which is especially important for faster feed rates and deeper cuts.

- Lower cost: Generally less expensive than 3-flute end mills.

- More effective for plunging: The two sharp cutting edges can be better for drilling or plunging cuts into the aluminum.

- Disadvantages:

- Rougher surface finish: With fewer flutes taking passes, the finish may not be as smooth as a 3-flute end mill.

- More prone to chatter: The uneven chip removal can cause vibration during cutting, which can lead to a poor finish.

3-Flute End Mills

- Advantages:

- Smoother surface finish: The additional flute distributes the cutting load, resulting in a finer finish.

- Less chatter: The more balanced cutting action helps to reduce vibration and improve surface quality.

- Can handle higher feed rates: With more flutes sharing the workload, you can potentially increase the feed rate compared to a 2-flute end mill.

- Disadvantages:

- Lower chip clearance: The smaller gullets may not evacuate chips as effectively, especially with deeper cuts or high feed rates. This can lead to chip re-cutting and a poor finish.

- Higher cost: Generally more expensive than 2-flute end mills.

Here's a quick recommendation:

- Use a 2-flute end mill for: Roughing cuts, hogging out material, or when a good surface finish is not critical.

- Use a 3-flute end mill for: Finishing cuts, shallow pockets, or when a smooth surface finish is important.

Ultimately, the best choice will depend on your specific application. Consider the factors mentioned above, such as the desired surface finish, chip clearance requirements, and your budget. Consult with CGS Tool for more information.