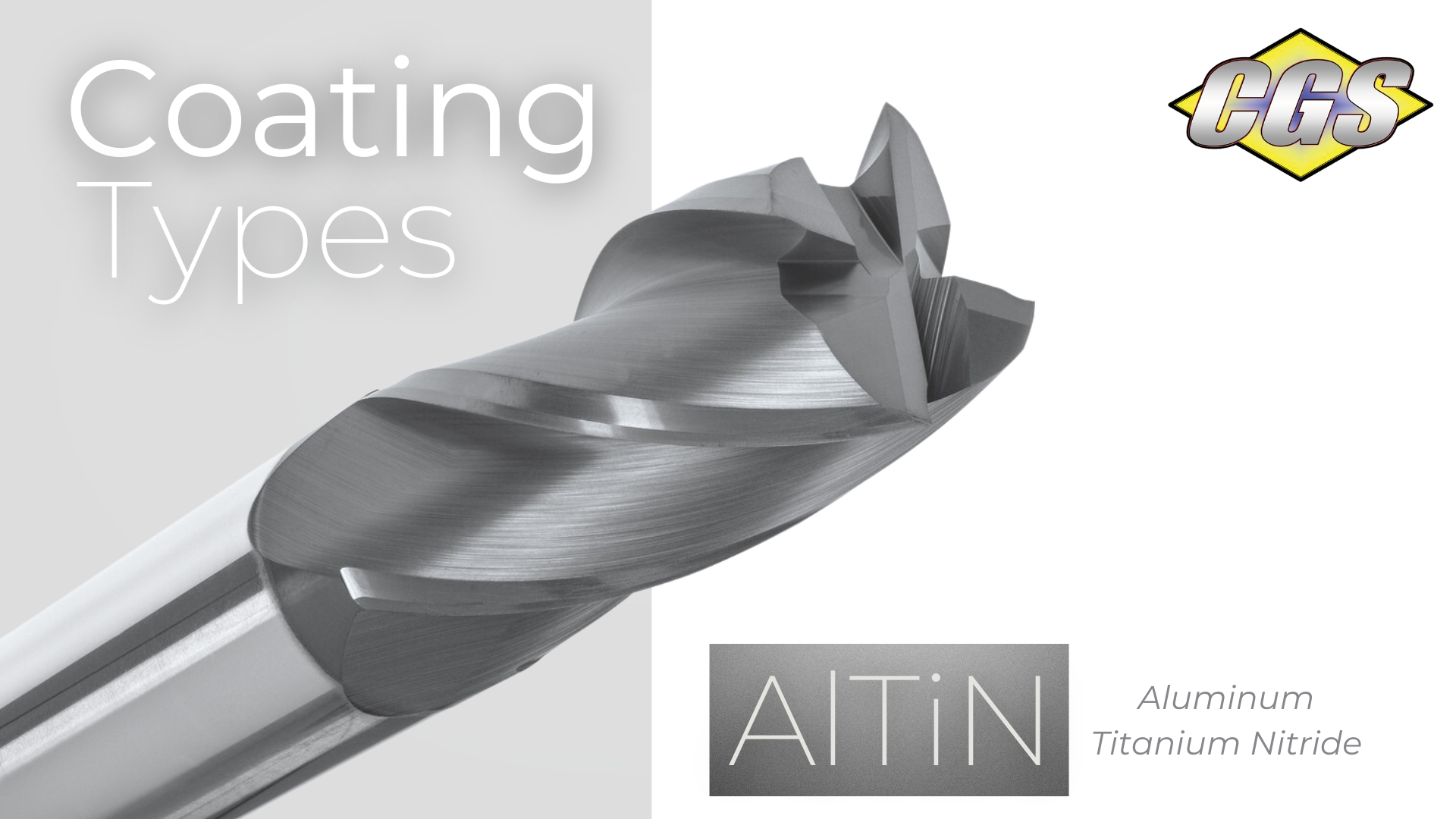

AlTiN coating, also referred to as Aluminum Titanium Nitride coating, is a popular and versatile choice for enhancing cutting tool performance. Here's a closer look at its properties and applications:

Composition and Benefits:

- Nitride Ceramic: AlTiN is a ceramic material formed by combining aluminum and titanium nitrides. This composition offers several advantages:

- High Hardness: It boasts exceptional hardness, surpassing even high-performing materials like titanium nitride (TiN) coating. This translates to superior wear resistance, allowing your cutting tools to stay sharper for longer.

- Excellent Thermal Stability: AlTiN maintains its hardness well at elevated temperatures, making it ideal for high-speed machining applications where heat generation is a concern. This allows for faster cutting speeds without compromising tool life.

- Oxidation Resistance: AlTiN offers good resistance to oxidation, further extending tool life in environments where oxidation can degrade cutting performance.

Applications:

- General Machining: Due to its well-rounded properties, AlTiN is a suitable choice for various machining applications, particularly when working with ferrous materials like steel and stainless steel.

- High-Performance Cutting: AlTiN's ability to withstand heat and maintain hardness makes it well-suited for demanding machining processes involving high cutting speeds and feeds.

- Difficult-to-Machining Materials: When dealing with challenging materials like stainless steel and titanium alloys, AlTiN coating provides the extra edge needed for efficient and clean cuts.

Additional Considerations:

- Broad Applicability: AlTiN is a versatile coating that can be applied to a wide range of cutting tools, including drills, milling cutters, and turning inserts.

- Environmentally Friendly: The PVD (Physical Vapor Deposition) process used to apply AlTiN is generally considered an eco-friendly option compared to traditional coating methods.

While AlTiN offers significant advantages, it's important to consider your specific needs. If you're primarily working with aluminum or cost is a major concern, other coatings like ZrN might be a better option. CGS Tool can help you determine the ideal coating for your application.